What cookstove and household biodigester projects are CCP label eligible

March 13, 2025 - Research

The ICVCM announced that projects using three cookstoves and one household biodigester methodologies are eligible for the Core Carbon Principles (CCP) label, provided they meet additional requirements beyond those in the methodology. This announcement comes as a boost to a sector plagued by over-crediting and general greenhouse gas (GHG) integrity concerns. It is important to note that across 203 Calyx Global-rated cookstove and biodigester projects, none are eligible for CCP labeling due to the additional requirements the ICVCM has set.

The approved cookstove methodologies are:

- Gold Standard – Methodology for Metered & Measured Energy Cooking Devices versions 1-1.2

- Gold Standard – Reduced Emissions from Cooking and Heating – Technologies and Practices to Displace Decentralized Thermal Energy Consumption (TPDDTEC) version 4.0

- Verra (VCS) – VM0050 – Energy Efficiency and Fuel-Switch Measures in Cookstoves version 1.0

The approved household biodigester methodology is:

- Gold Standard – Methodology for Animal Manure Management and Biogas Use for Thermal Energy Generation version 1.0

Additional requirements for receiving the CCP label

Calyx Global welcomes the inclusion of these methodologies to CCP labeling, though crucial eligibility requirements have made project-specific eligibility very rare. The following conditions must be met for specific projects to be eligible:

- The default fraction of non-renewable biomass (fNRB) value of 0.3 from the latest version of CDM Tool 33 is applied for emission reductions achieved on or before December 31st, 2025, or the source of data for fNRB in mitigation activities is from the ‘Modeling Fuelwood Savings Scenarios’ (MoFuSS) model as per CCP Eligible Program approved project documentation.

- Fuel consumption must be determined either by using a Kitchen Performance Test (KPT) or Controlled Cooking Test (CCT), or by using methodology default values with cross checks on fuel savings.

- For charcoal projects, a direct charcoal emission factor (which may include production emissions) or a wood-to-charcoal conversion factor of 4:1 is used.

Assessing cookstove and biodigester projects

Of the 203 cookstove and biodigester projects Calyx Global has rated, no project meets these requirements in full, though we have seen evidence of alignment with one or two of these criteria. For example, the GS Metered & Measured (GS-Metered) methodology requires a 4:1 conversion ratio of wood to charcoal for charcoal fuel emissions. We have also rated numerous projects employing the in-field (and more reliable) KPT.

At their core, these three conditions target the risk of over-crediting, which has the most significant impact across our rated cookstove and household biodigester projects:

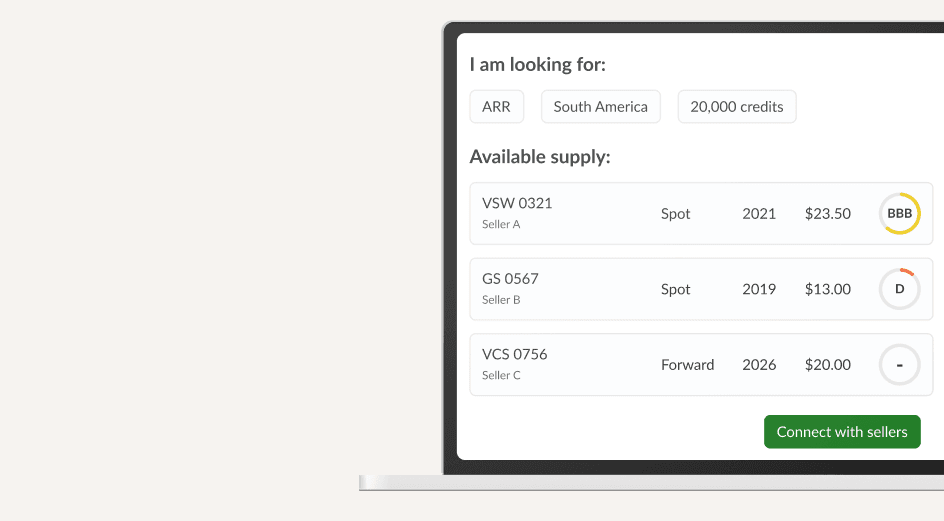

Before we dive into some of the core conditions of the new ICVCM announcement, here is a reminder of the Calyx Global rating distribution for cookstove and biodigester projects:

Before we dive into some of the core conditions of the new ICVCM announcement, here is a reminder of the Calyx Global rating distribution for cookstove and biodigester projects:

Key GHG integrity issues

1. The fraction of non-renewable biomass (fNRB)

The principal issue this announcement targets is the reduction of over-crediting risk due to project-specific values for fNRB, as compared to independent benchmarks provided by MoFuSS or a CDM default. Since October 2023, Calyx Global has applied the MoFuSS model to benchmark projects claiming to conserve biomass, as we believe that, where available, it is the most comprehensive and high-quality independent assessment of non-renewable biomass.

MoFuSS is a GIS-based model that simulates the spatio-temporal impacts of woodfuel harvesting dynamically. The model derives fNRB values at national and subnational scales by observing the dynamics of above-ground biomass via integrating drivers of land change, woodfuel demand sources and end-user technologies.

What is fNRB? Biomass fuel can be considered renewable in terms of GHG emissions if the biomass regrows at least at the same rate that it is harvested. In this renewable scenario, all emissions from the removed biomass are offset by the natural regrowth of biomass. Conversely, biomass is considered non-renewable when the harvesting rate exceeds the natural regeneration rate in a given region across a given time period, resulting in net emissions. Therefore, in all projects that avoid or reduce biomass usage, the emission reductions are calculated based on the fNRB. The higher the fNRB, the more emission reductions the project can claim. For more on fNRB and its impact on cookstove and biodigester carbon projects, we prepared a deeper dive into the major fNRB calculation approaches and Calyx Global’s tools for cross-checking project estimates. |

Calyx Global supports the adoption of MoFuSS to derive project values for fNRB, as across our rated cookstove and household biodigester projects, the average overestimation of project values against independent scientific literature has been approximately 230%. This has been largely due to average project values for fNRB ranging from 0.8-0.95, while benchmarks are usually between 0.25-0.35. Steps to reduce the overestimation of this variable are required to reorient the cookstove sector toward higher GHG integrity. The CCP’s fNRB requirements are a welcome addition.

2. Measuring fuel consumption

Another core component of reducing over-crediting, highlighted by the CCP and relevant for both project types, is the accurate estimation of fuel consumption in both the baseline and project scenarios. For projects that claim to conserve biomass, household fuel consumption is crucial in determining emission reductions. The CCP announcement has allowed for both KPTs and CCTs, though Calyx Global analysis finds that KPTs are more effective in determining realistic fuel consumption estimates than CCTs. KPTs measure fuel consumption via a three- to four-day in-field procedure in which surveyors weigh a household’s fuel in the morning and evening to capture daily fuel consumption.

Fuel consumption by methodology

GS TPDDTEC requires the use of in-field KPTs to determine fuel consumption, as compared to AMS-II.G or GS Simplified (not CCP-approved) that allows for the calculation of emission reductions based on manufacturer or lab-based stove efficiencies. Tests conducted in a laboratory setting under controlled conditions or certain in-field controlled-cooking testing may not capture daily cookstove performance and usage, which tends to differ in the field [1][2][3][4]. Reasons for this can include:

- Variable field conditions (i.e., moisture and quality of the wood, temperature or wind) and potential improper specifications (e.g., handcrafted stoves).

- Laboratory tests only “test” specific cooking tasks (e.g., boiling water) that are not representative of the majority of cooking tasks.

- The tester’s knowledge of how to operate the stove compared to end users (e.g., filling the stove with fuel exactly when needed, engaging in extra work to ensure proper use of the stove, maintaining the stove according to best practices).

VM0050 Energy Efficiency and Fuel-Switch Measures in Cookstoves, v1.0 methodology is the latest Verra methodology that has been active since October 2024 and aims to replace VMR0006. This methodology also requires the use of KPTs or UNFCCC defaults to derive baseline fuel consumption. For project fuel consumption, it requires the use of KPTs, direct fuel measurement or fuel purchase monitoring for projects that use fossil fuels or bioethanol. There are no credits verified under the methodology yet, though we consider VM0050 an improvement over its predecessor, VMR0006.

The Gold Standard Methodology for Animal Manure Management and Biogas Use for Thermal Energy Generation allows for KPTs, or default values multiplied by the number of persons served per household. Project fuel consumption is measured via field performance tests.

GS-Metered requires individual devices to measure project fuel use. By requiring direct fuel measurement, GS-Metered removes the uncertainty and bias that could otherwise occur during surveying or in-field testing. Also, GS-Metered ensures conservativeness of project fuel consumption by requiring a cap on projects’ reported fuel use values. Any fuel use reported above the methodological cap must either be excluded from emission reduction calculations or the project must provide additional justification for the high value.

3. Wood-to-charcoal conversion

As per our recent introductory blog posts for GS-Metered, we introduced some of the important changes for integrity that this methodology can bring, such as the requirement for a wood-to-charcoal conversion factor of 4:1. This figure determines the amount of wood required to make charcoal via pyrolysis. This means that for every 1 kilogram of charcoal produced, approximately 4 kilograms of wood are needed as input. The accuracy of this figure depends on the kiln efficiency and wood type used as input, and as such, is situationally dependent.

The latest version of VM0050 also promotes a 4:1 ratio, though it permits a 6:1 ratio if substantiated with government-endorsed and approved values. The in-development Clean Cooking Alliance methodology ‘4CLEAR’ also asserts that, after an extensive literature review, a 6:1 ratio is reasonable. Despite this, the UNFCCC has recently re-affirmed that the benchmark for this figure should be 4:1, reduced from the previous benchmark of 6:1 for CCP eligibility.

Calyx Global assessments of projects utilizing TPDDTEC and GS-Metered

Calyx Global has rated three projects under GS-Metered and 53 under GS TPDDTEC. None of these projects we have rated meet CCP requirements.

In the case of GS-Metered projects, projects failed to align with CCP due to their overestimated fNRB values. This is in part because projects could still utilize Tool 30 to determine their own fNRB value under both methodologies, which can critically impact a given project’s over-crediting.

In the case of GS TPDDTEC, all of our ratings are of projects using previous methodology versions, which are not eligible under the CCP label. Similar to GS-Metered, fNRB overestimation is common across these projects. In addition, for projects that utilize charcoal, we find an overestimated ratio for converting the amount of woodfuel used to make charcoal compared to CCP requirements.

Interestingly, across all 56 projects Calyx Global has rated, fNRB overestimation is a continuous factor limiting the GHG integrity of the credits issued. In this sense, the CCP requirement to limit fNRB to a 0.3 default or utilize MoFuSS would also improve the GHG integrity of those projects using non-eligible methodologies. If those improvements were also combined with alignment to wood-to-charcoal conversion, alongside KPT use, for example, we would expect to see higher ratings.

Beyond GHG Integrity: Cookstove potential for SDG contributions

Cookstove projects have traditionally been a popular choice among carbon credit buyers for their potential to contribute not only to climate but to a wide variety of Sustainable Development Goals (SDGs), including health, energy, gender, poverty reduction, employment, sustainable consumption and deforestation. According to our SDG ratings, cookstoves stand out as the highest-ranked technology project for SDG Impact, showing their great potential to also generate significant positive impacts beyond carbon.

Can quality exist outside of CCP eligibility?

In short, yes. Of the over 200 projects that Calyx Global has rated, we do note that two are in our Tier 1 category (i.e., A or above). These projects, while not eligible for the CCP label, have a combination of lower non-additionality and over-crediting risks. Our rating process consists of numerous quantitative and qualitative components and while credits generated by a project may not align with all CCP criteria, they may be conservative in other ways.

Though the requirements to achieve CCP labeling under eligible methodologies are more conservative than the vast majority of projects we have rated, Calyx Global believes that these labels will help buyers better discern GHG integrity while encouraging projects to meet higher standards.

Citations

[1] Wathore, R., Mortimer, K. & Grieshop, A.P. (2017). In-Use Emissions and Estimated Impacts of Traditional, Natural- and Forced-Draft Cookstoves in Rural Malawi. Environ. Sci. Technol. 51, 1929–1938. Accessible at: https://pubs.acs.org/doi/10.1021/acs.est.6b05557.

[2] Zhang, Z. et al. (2017). Systematic and conceptual errors in standards and protocols for thermal performance of biomass stoves. Renew. Sustain. Energy Rev. 72, 1343–1354. Accessible at: https://ideas.repec.org/a/eee/rensus/v72y2017icp1343-1354.html

[3] Gill-Wiehl, A., Price, T. & Kammen, D. M. (2021). What’s in a stove? A review of the user preferences in improved stove designs. Energy Res. Soc. Sci. 81, 102281. Accessible at: https://www.sciencedirect.com/science/article/pii/S2214629621003741.

[4] Muralidharan, V. et al. (2015). Field testing of alternative cookstove performance in a rural setting of western India. Int. J. Environ. Res. Public. Health 12, 1773–1787. Accessible at: https://www.mdpi.com/1660-4601/12/2/1773.

Keep up with carbon market trends

Get the monthly newsletter and stay in the loop.

Trusted By