An introduction to bio-oil geological storage projects

February 6, 2025 - Research

The geological storage of bio-oil has been described by proponents as turning back the clock on fossil fuel extraction by reversing the flow of carbon and pumping oil back underground. Although it is a compelling analogy, to date, very few companies have entered this niche of the carbon dioxide removal (CDR) market.

In this blog post, we will dive into the details of bio-oil storage projects and discuss the advantages and constraints faced by this innovative new synthesis of nature-based and engineered CDR solutions: nature pulls down the CO2 and technology takes it underground.

Bio-oil methodologies in the VCM

Currently, two methodologies have been developed for the implementation of bio-oil projects. In 2021, Puro.earth published a Geologically Stored Carbon protocol which applies to various forms of captured CO2. As of now, no bio-oil projects have been registered under this methodology.

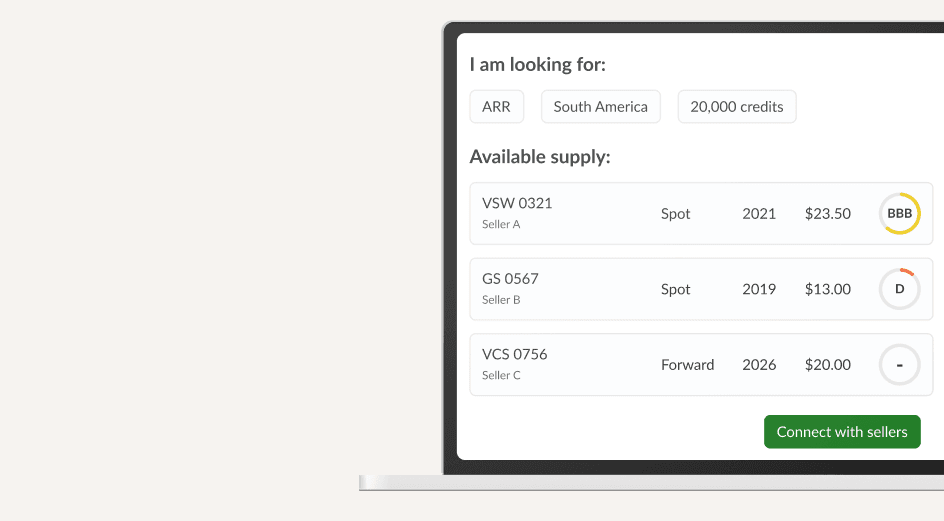

More recently, in January 2024, Isometric certified a Bio-oil Geological Storage protocol. Shortly thereafter, they verified the very first bio-oil project in the voluntary carbon market (VCM). While the VCS has also published a Carbon Capture and Storage (CCS) methodology, they have not yet released a module that pertains to bio-oil injection. Calyx Global has recently rated the first bio-oil project in the VCM and will continue publishing ratings for bio-oil injection projects as they emerge.

What is bio-oil and how is it stored?

Bio-oil, also known as pyrolysis oil or bio-crude, is produced through a fast pyrolysis process where biomass – often agricultural waste or forest thinnings – is heated very quickly to high temperatures (~350–650°C), in an environment with low or no oxygen[1]. By weight, bio-oil is composed of 40-50% carbon and 20-30% water, along with various other compounds[2].

Bio-oil is not very energy-dense, making it a poor bio-fuel. However, the high carbon content, as well as the natural tendency for bio-oil to solidify over time, make it a prime candidate for geological storage. Bio-oil is quite acidic (pH 2–3) and must be treated to improve stability prior to injection. Following pretreatment, it can be injected below the water table into natural or human-made geologic features, such as mines, reservoirs, or decommissioned oil wells. The result is long-term sequestration and storage of carbon that otherwise would have continued to cycle through natural systems.

Why is bio-oil injection considered a carbon removal rather than an emission reduction?

In a business-as-usual scenario, plants remove CO2 from the atmosphere and some of the CO2 ends up as organic waste – either on agricultural fields or on a timber operation after logs have been cut or sawn. These forms of organic waste would either naturally decompose over time or be burned/destroyed, both of which release CO2 back into the atmosphere.

The uptake and release of CO2 through plants occurs in a continuous cycle, within a year or so (for agriculture) or over many years (for wood waste). Over the entire cycle, the net carbon stock change is zero on land and in the atmosphere. Bio-oil projects interrupt these natural carbon cycles, removing carbon from the plant-atmosphere cycle and diverting it to permanent storage.

The benefits of bio-oil injection as a CDR approach

Bio-oil injection has a number of advantages. It is intrinsically additional as there is no purpose for underground storage other than the removal of CO2 from the atmosphere. The process is efficient. Unlike direct air capture, it leverages the power of plants to sequester atmospheric CO2 through photosynthesis. Finally, carbon storage is permanent. Bio-oil’s tendency to sink and solidify over time reduces the risk of reversals, safeguarding the permanence of removals over long timescales.

Another benefit, touted by bio-oil proponents, is that bio-oil can be produced using a variety of waste biomass streams that are inexpensive and readily available in large quantities. For example, each year American farmers produce around 75 million tons of agricultural waste just from corn production, which includes corn husks, stalks and cobs[3].

This idea of “waste” biomass should be tempered by an important cautionary note. First, to the extent that these waste streams already have some uses, bio-oil will compete with those uses. Second, and most importantly, “waste biomass” is a critical component of the ecosystems where it occurs. Rigorous sustainable biomass sourcing criteria are key to avoiding negative environmental impacts as well as project leakage (such as increased need for fertilizers).

Complete removal of biomass residues from agricultural and forested lands can lead to a decline in soil health. Soil carbon, fertility, structure and water-holding capacity would all decrease with no input of “waste” organic matter. However, when implemented sustainably, bio-oil projects can be innovative solutions to deal with unwanted waste.

Current bio-oil projects in the VCM

The Isometric registry hosts the only bio-oil project in the VCM: Charm Kansas Bio-oil Geologic Storage (project code 7BDE). The project has only generated 107 credits (of which 70 credits have already been retired), but Charm Industrial, the project developer, aims to develop methods to increase the amount of carbon they can sequester annually.

Implementation barriers and impediments to scalability

Allowing crop plants and trees to do the hard work of capturing CO2 from the atmosphere is efficient; however, transportation of raw biomass is not. Energy-intensive transportation represents one of the major hurdles faced by bio-oil projects. Work is underway to allow mobile pyrolyzers to travel to where biomass waste is plentiful. On-site bio-oil production would concentrate carbon relative to bulky raw biomass feedstocks, reducing transportation costs and leading to a more energy-efficient process.

Cost is currently the major impediment to the scalability of bio-oil injection as a CDR approach. In addition to production, transportation and injection costs, research and development costs are substantial. Mobile pyrolyzers with the capacity to process large quantities of biomass are still being developed. As the technologies develop and capacity increases, the cost of such credits is likely to decrease.

Environmental and social safeguards and contributions

This process, like any other carbon project, involves inherent environmental and social risks. However, it is important to note that both Puro.earth and Isometric proactively address these challenges by implementing environmental and social safeguards for their projects. For example, Isometric mandates an assessment of the suitability of injection sites to ensure that geological formations are stable and appropriate for long-term carbon storage.

Simultaneously, Puro.earth mandates lifecycle assessments that evaluate all environmental impacts associated with the project, including soil and groundwater contamination as well as geological integrity. Additionally, it requires that project proponents source biomass from sustainable origins, a crucial step to prevent negative impacts on biodiversity, forest conversion and food security.

It is worth highlighting that when these projects are properly implemented, they may substantially contribute to sustainable land use and enhance biodiversity by advocating for responsible forestry and agricultural management practices (SDG 15). Moreover, they may bolster local economic development by creating jobs (SDG 8) and improving livelihoods (SDG 1).

Finally, both Puro.earth and Isometric require projects to demonstrate that effective consultation with affected communities was conducted and integrate their feedback and needs into the project's design, implementation and benefit-sharing framework. However, it should be noted that each project is unique; thus, it is crucial to perform a case-by-case analysis to ascertain how effectively the reported mitigation and management measures, as well as the implemented processes, address the risks associated with the project's specific context and location.

Conclusions and considerations

Despite challenges in terms of scale and efficiency, this new project type has the potential to contribute to climate goals while utilizing organic waste. However, there is room for improvement. Every ton of CO2 removed through bio-oil injection creates one ton of CO2 emissions. In other words, to generate one credit, two tons of bio-oil CO2 must be injected. Improved efficiency over time may help tip the balance to more carbon storage and fewer carbon emissions.

This carbon credit category is the latest expansion of Calyx Global’s available and continuously growing scope of ratings, so stay tuned for new ratings announcements.

Citations

[1] Venderbosch, R.H. (2019). Fast Pyrolysis. In Thermochemical Processing of Biomass, R. Brown (Ed.). Accessible at: https://doi.org/10.1002/9781119417637.ch6

[2] Basu, P. (2018). Biomass gasification, pyrolysis and torrefaction: practical design and theory. Accessible at: https://www.sciencedirect.com/book/9780123964885/biomass-gasification-pyrolysis-and-torrefaction

[3] Farm-Energy. (2019). Corn stover for biofuel production. Accessible at: https://farm-energy.extension.org/corn-stover-for-biofuel-production/

Keep up with carbon market trends

Get the monthly newsletter and stay in the loop.

Trusted By

Next Up